Types of Bridge Bearing

Types of bridge bearing

1. Elastomeric Bearing

a.Plain elastomer pads

b.Laminated Elastomeric bearings

2.Sliding bearing Mechanism

a. PTFE sliding material

b.Alternative sliding material

3.High load multi Rotational building:

a.Pot bearing

b.Disc bearing

c.Spherical bearings

4. Fabricated steel mechanical bearing

a.Rocker bearing

b.Rocker cum rolling bearing

Elastomeric Bearing:

It consists of

elastomer manufactured from synthetic or natural rubber and can take both

translation and rotation movements through elastomer deformation. The ability

of elastomer to carry large vertical loads is because of reinforcement

provision that prevents lateral bulging of elastomer.

There are number of

elastomeric bearing pads classified based on types of reinforcements used. For

example, steel reinforced, plain, fiberglass reinforced and cotton duck

reinforced elastomeric bearing pads

Strength and response

of each type is different, steel reinforced elastomeric bearing is the

strongest one and plain elastomeric pad is the weakest.

a.Plain Elastomeric Bearing

Plain elastomeric bearing with the

simplest structure among all bearing products is exclusively manufactured

from natural rubber or neoprene rubber. It is considered to be a low cost

choice for short span bridges, prefabricated

structures, buildings as well as flyovers, etc.

b.Laminated Elastomeric Bearing

It is manufactured through the process of

vulcanization and moulding to form a homogeneous unit with layers of steel

plated embedded in. Comparing with plain elastomeric bearing, this one has

higher vertical load capacity, excellent vibration and sound isolation. It is

ideal for bridges with short span and flyovers, etc.

a.Plain Elastomeric Bearing

Plain elastomeric bearing with the

simplest structure among all bearing products is exclusively manufactured

from natural rubber or neoprene rubber. It is considered to be a low cost

choice for short span bridges, prefabricated

structures, buildings as well as flyovers, etc.

b.Laminated Elastomeric Bearing

It is manufactured through the process of

vulcanization and moulding to form a homogeneous unit with layers of steel

plated embedded in. Comparing with plain elastomeric bearing, this one has

higher vertical load capacity, excellent vibration and sound isolation. It is

ideal for bridges with short span and flyovers, etc.

2.Sliding Bearing Mechanism

Sliding bearing consist of two

metal plates, commonly stainless-steel plates, that slide relative to each

other and hence makes room for translational movement and lubricating material

between them.

Sliding Bridge Bearing

A friction force is generated

in sliding bearing and it is imposed on substructure, superstructure and

sliding bearing itself. So, it may be required to provide lubricant such as

polytetrafluoroethylene (PTFE) to decline generated friction.

Sliding Bridge Bearing

A friction force is generated

in sliding bearing and it is imposed on substructure, superstructure and

sliding bearing itself. So, it may be required to provide lubricant such as

polytetrafluoroethylene (PTFE) to decline generated friction.

It is specified by ASSHTO that

sliding bearing cannot be used unless the bridge span is smaller than 15m. This

is because sliding bearing cannot be purely used if the bridge experiences

rotation movement.

However, the span restriction

for sliding bearing utilization can be disregarded when it is used in

combination with other bearing types.

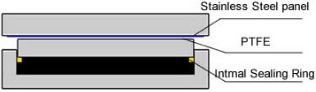

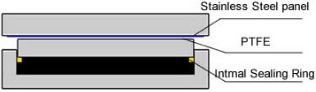

PTFE Sliding Material.

PTFE top elastomeric bearing, a variation of traditional laminated elastomeric bearing ,

features a layer of PTFE bonded to top surface of the bearing. In conjunction

with lubricant in the dimples of PTFE, the bearing allows for excellent sliding

movements with reduced friction coefficient.

Pot Bearing

Pot Bearing is the widest used type designed for

structures using the incremental launching methods, highways and railways, etc.

PTFE top elastomeric bearing is fitted in the steel pot plate to ease the

sliding movements with the help of a stainless steel panel welded on top steel

plate.

Disk Bearings for Bridges

Both vertical loads and lateral

loads are supported by elastomeric disk and metal ring in the center of the

bearing respectively.

Sliding Bridge Bearing

A friction force is generated

in sliding bearing and it is imposed on substructure, superstructure and

sliding bearing itself. So, it may be required to provide lubricant such as

polytetrafluoroethylene (PTFE) to decline generated friction.

It is specified by ASSHTO that

sliding bearing cannot be used unless the bridge span is smaller than 15m. This

is because sliding bearing cannot be purely used if the bridge experiences

rotation movement.

However, the span restriction

for sliding bearing utilization can be disregarded when it is used in

combination with other bearing types.

PTFE Sliding Material.

PTFE top elastomeric bearing, a variation of traditional laminated elastomeric bearing ,

features a layer of PTFE bonded to top surface of the bearing. In conjunction

with lubricant in the dimples of PTFE, the bearing allows for excellent sliding

movements with reduced friction coefficient.

High load Multi Rotational building

Pot Bearing

Pot Bearing is the widest used type designed for

structures using the incremental launching methods, highways and railways, etc.

PTFE top elastomeric bearing is fitted in the steel pot plate to ease the

sliding movements with the help of a stainless steel panel welded on top steel

plate.

Disk Bearings for Bridges

Rotation movement is accommodated

through the deformation of elastomer whereas the translation movement is

considered through the application of PTFE slider.

The utilized elastomer should

be adequately hard to support vertical loads without suffering large

deformations and sufficiently flexible to allow rotational movement.

Both vertical loads and lateral

loads are supported by elastomeric disk and metal ring in the center of the

bearing respectively.

Spherical Bridge bearing

Lead rubber bearing, as its name implies, has a

lead plug in the middle of the bearing that will assist the bearing to absorb

earthquake-generated forces, extending the structure vibration period. In this

way, lead rubber bearings protect buildings or structures from damages and

severe deformations caused by earthquake.

Curved Bearings for Bridges

Due to the fact that both

gravity loads and curved geometry generate lateral resistance against and

consequently lateral movement would be limited, that is why polytetrafluoroethylene (PTFE) slider is adhered to the bearings in order to

make rooms for lateral movements.

Spherical Bridge bearing

Spherical bridge

bearing features its precision-machined steel plates with concave ad

convex surfaces. And it can accommodate large movements and rotations in excess

of +/- 0.03 radians. Spherical bridge bearings can be applied to structures

with large turning angles, wide and curved bridges regardless of low

temperatures even under -30℃.

Lead rubber bearing, as its name implies, has a lead plug in the middle of the bearing that will assist the bearing to absorb earthquake-generated forces, extending the structure vibration period. In this way, lead rubber bearings protect buildings or structures from damages and severe deformations caused by earthquake.

Curved Bearings for Bridges

If curved

bearing is cylindrical, then it only accommodates rotation movements. However,

both rotation and translational movements can be dealt with if curved bearing

is spherical.

Fabricated steel mechanical bearing

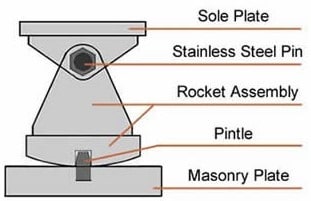

a.Rocker Bearing

Rocker is an expansion

bearing composed of curved surface at the bottom, which accommodate

translational movement and a pin at the top makes room for rotation movement..

PIN bearing:

Pin bearing is a fixed

bearing that make room for rotation movement through the application of steel

pin. It has similar structure and component like rocker bearing apart from the

bottom of pin bearing which is flat and fixed to the concrete pier.

Roller Bearings for Bridges

Roller bearing can be

used in the construction of reinforced concrete and steel bridge structure.

There are two main configurations including single roller bearing which is

composed of one roller placed between two plates and multiple roller bearing

that consist of several rollers installed between two plates.

Multi roll bearing make room for translation movement only and

rotation movement can be accommodated if rollers are combined with pin bearing.

Multiple roller bearings are expensive and support considerably large vertical

loads.

b.Rocker cum rolling bearing

These type of bearings consists of rollers sandwiched between a

saddle plate and a bottom plate. Rocker cum roller bearings offer longitudinal

movement through rollers which roll along guide bars attached to saddle plate

and bottom plate. Rotational movement is through a rocker pin which gives a

see-saw rocking motion to the top plate. The rollers are connected by a spacer

plate for unidirectional movement.

The Information that you have shared was really very useful to us. If anyone wants to know about Ecooo. I think this is the right place for you! bearing pads for bridges

ReplyDeleteNice Information

ReplyDeletefor more info: Elastomeric Bearings Suppliers

Good information Elastomeric Bearing Suppliers

ReplyDeleteFor information visit our services

Bridge Bearing

Bridge Expansion Joints

Rehabilitation And Installation Of Bridge Bearings

Dam Gate Seals

Industrial Rubber Products

This comment has been removed by the author.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteI love how you broke down the complexities of cable compounds into easily digestible information. Your writing style is engaging and made learning about this topic enjoyable .Thank you! for more informationcable compound

ReplyDeleteThanks for sharing this useful information with us in form of blog. I would like to share about Marc Bearings, one of the leading Bearing Manufacturer in India. If you are looking for best bearings in India then contact them now.

ReplyDeleteCool

ReplyDeleteNice. Thanks for the great information for Bearings Exporter From India. Tapered roller bearings are bearings especially constructed to endure both radial and axial loads simultaneously even under extreme environmental conditions and varying speeds.

ReplyDeleteNice. Thanks for the great information for Bearing Manufacturer in India. Industrial machines and equipment depend on several mechanical components that ensure their efficient and seamless performance throughout the production process.

ReplyDelete