Autoclaves

Autoclaves

Autoclaves for rubber product vulcanization are available a

wide range of sizes to suit the product type. The main use for autoclaves is in

the production of extrusions, sheeting and components which are of unsuitable

size of construction for convention mould vulcanization.Examples of this type of product can range from

roller coverings to hand-built products such as

footwear.

The Machinery:

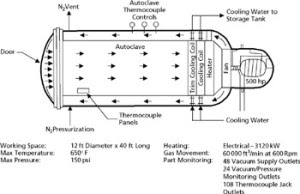

Autoclaves are predominantly

cylindrical pressure vessels with lids or doors to process the rubber parts

that require exposure to elevated pressure and temperature. They are available

in a wide range of sizes and design pressures in horizontal (or sometimes

vertical) configuration.

The key component of the autoclave is the

door. For a manufacturer, this is also the critical component in

cost of autoclave construction.

Two types of autoclaves are in common use – Non-jacketed and Jacketed.

In the non-jacketed type, steam is introduced directly into the autoclave chamber. The steam condenses on the walls of your autoclave and on the surface of your rubber products under vulcanization. However, this leaves behind a mark on the surface of your product. And when you adopt preventive measures, you end up getting a dull finish on your rubber products. For some products like Radiator hoses for cars, you can cure in open steam.

The jacketed autoclaves has a double wall. Steam is circulated in the jacket to provide heating. There is no direct contact of steam with your rubber products. An inert gas (like Nitrogen) is then introduced in the autoclave to eliminate oxidation. Gases are normally poor conductors of heat and thus increases the curing time.

Steam curing is still the more widely used method and

involves the use of a gas or electric boiler supplying steam

to a

single-cased autoclave. Increasing

in popularity is the use of hot atmosphere curing in

autoclaves, where the internal pressurising medium (either air or nitrogen) is heated by

electric heater elements. This method has the

advantage of providing independent control of pressure

and temperature, unlike with steam, and

eliminating the detrimental effects

of condensation. Use of nitrogen also eliminates

surface deterioration of the product from oxidation.

An advantage of the autoclave for smaller components, is that a large

volume

of the same or different products can be vulcanised at the same time,

provided that the curative systems in use do not interact between the different

compounds. It is usual to support extrusions

and low hardness products in talc. Products

formed on mandrels

and sheeting, for example, are cloth wrapped to prevent distortion.

The temperature is raised using a number of steps to achieve uniformity of temperature

throughout the product

mass, before the final vulcanisation stage is reached.

It may be necessary to use a gas or steam circulatory system to ensure uniformity of temperature

throughout the whole of the autoclave and its contents.

Comments

Post a Comment