Fluid Bed curing

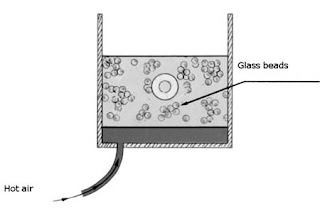

Fluid Bed System

This system, developed by Rapra during the period 1959 to 1974 uses the principle of fluidisation of particles by the passage of air through the mass. In its simplest form the powder, usually glass

beads (ballotini), is held in a metal trough

in the lower portion of which lies a layer of porous ceramic tiles, above the air pipes and heating means. Passage of

the heated air through the ballotini causes fluidisation. There is some degree of loss of fluidisation immediately above the profile being vulcanised if the fluidisation is from

below, but this can be improved by using side entry for some of the air.

After removal of the vulcanised product it is necessary to remove the glass beads from

the product surface. Ultrasonic cleaning units can be used for this purpose. It is also necessary to clean the glass beads from time to time to remove vulcanisation products from their surface.

The disadvantages are that certain products , such as flat

profiles which resemble conveyor belts, can shift the glass beads in the tank.

The glass beads can easily stick to certain soft materials, which is why great

emphasis is placed on the cleaning of the product.This is done with the aid of

revolving brushes and high pressure washing.

Comments

Post a Comment